I don’t think there is a simple way, but first, do you have reverse current protection, the way you described it if one battery was to fail the other battery would just try to charge it thus you get no redundancy. If the 2 batteries are paralleled they will have the same voltage so there is no use for 2 voltage sensors, what you do get from 2 power modules is more current and power redundancy.

So in your current setup, assuming you don’t have reverse current protection, if one battery was to fail(a cell dies) your drone would just fall from the sky because the good battery would use all it’s current to charge the other battery until a current sensor overheats and explodes. I wouldn’t worry about it tho, as that is not something that just happens, what is possible is that a battery disconnects itself, in such case both your PM’s would still be returning the voltage just one PM would say that there is 0A current(being that there is noise it woudn’t even say 0A). All that means is that it is hard for the autopilot to say “ah, I lost a battery, better go home”.

That is where smart batteries come into play, but being that there are so few on the market right now and that even less people use them, ardupilot doesn’t do much with the data.

Now, what you can do is make your own redundancy checker with an arduino or similar.

First, you need an arduino with analog inputs, we connect the current sense line to the arduino as well as the autopilot.

You can use high power diodes for reverse current protection.

Now you connect all that up and check the current’s on both analog inputs. When the drone is in flight both power modules should show close to same current, but if one battery fails or a cable disconnects one of the power modules should show no current, you can then check on the arduino if the other power module is sending out a lot more current, and if so you change flight mode to rtl with a serial message to the autopilot. That would cost you probably around 50-100$ depending on the diodes you use and comes with a large downside of a diode voltage drop.

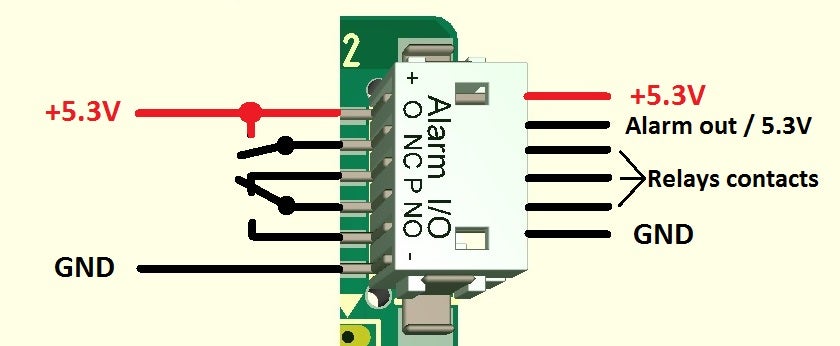

Another way would be to use relays or mosfets and trigger them with an arduino depending on the current direction although I don’t know how you’d do that.

I have a close to same setup with one major difference(more batteries):

- Pixhawk 2.1

- 6x 4.5Ah 6S batteries

- Hexacopter with 22" props

- 2x MAUCH 200A + 5v modules

besides the 2 power modules I have another 5V line for the servo rail

And I just added automotive 100A fuses to each battery but that approach wouldn’t work for you as you have 2 batteries total , you will blow your good battery fuse before you blow the dead battery fuse.

In my case, if a battery cell was to fail all the other batteries would try to charge it up causing it to have high current going in and blowing the fuse, the load would be spread to multiple batteries causing them to have at most 25A more current for a very short period of time. And if one battery fails I just don’t care and continue with my flight. This was more of a protection in case I plug in an low voltage battery among the full ones.

I would say you have no need to worry as that is very slim chance it would be necessary unless there is a mechanical fault(something pierces the battery(bullet, another drone), if that happen’s you’re already going down anyway.

Best of luck