06 - Prototype Frame v2.4.7

Okay, here we go. This is the first in a series of frames that will hopefully improve as this blog continues.

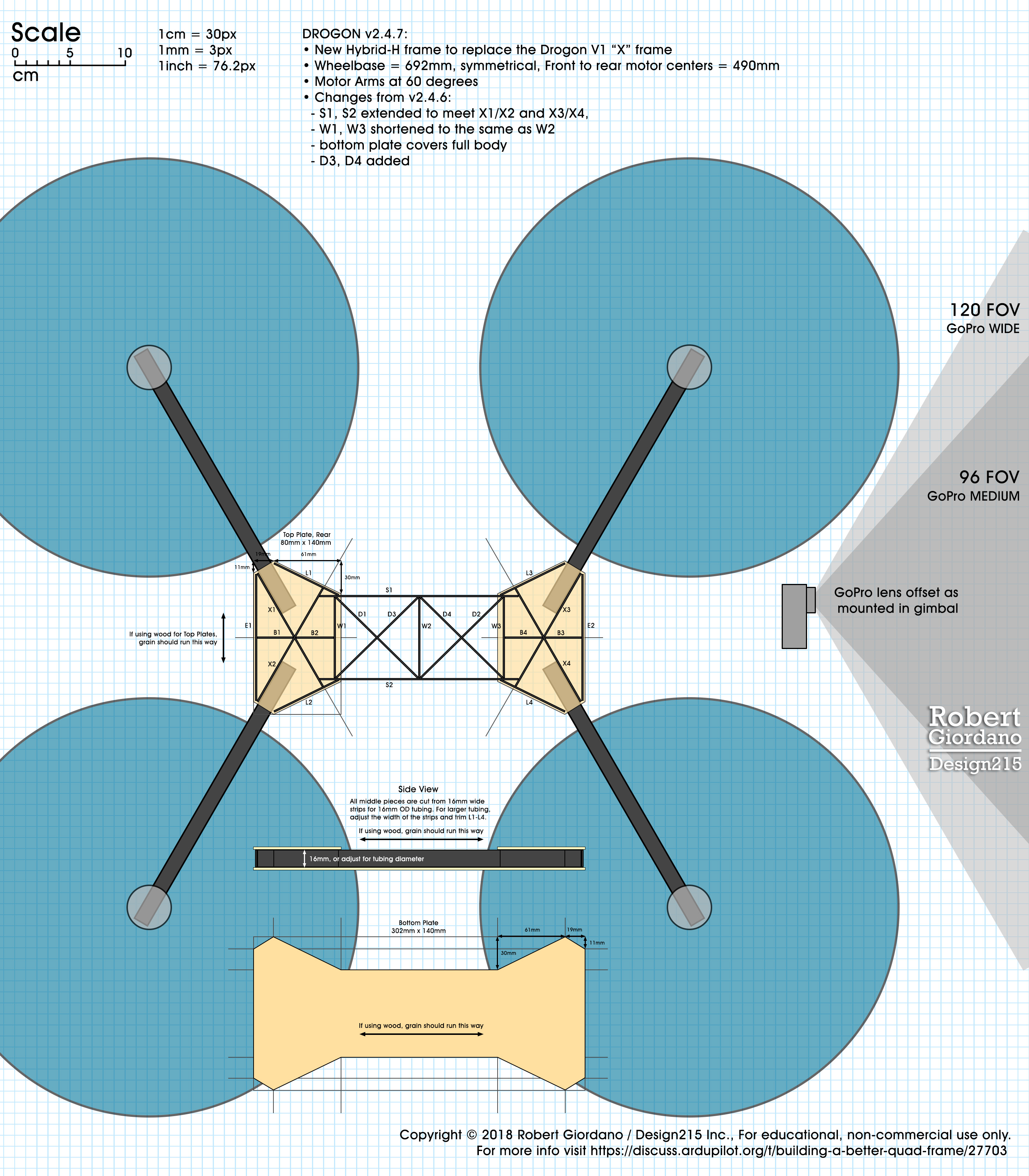

You might notice the picture says v2.4.6 while the title of this post says v2.4.7. That’s because I just made some improvements to the design, based on my tests. I’ll be posting the complete v2.4.7 design below. By the way, the frame is on the scale upside down. You are looking at the bottom

What is This Thing?

This is NOT a final product! This is a quadcopter frame that is light, stiff, cheap, and easy to build. Its has the following specs:

- It weighs 150g as pictured (174g with complete motor mount hardware).

- Its has a 680mm wheelbase optimized for 15" props, with clearance for 16" props.

- It is torsionally stiffer than many similar sized commercial frames (more on that below).

This is meant to be a very general purpose frame. You could hang a camera or gimbal underneath and put legs on it. You could add extension tubes and have a front mounted gimbal that clears the props. You could do something in-between. It is designed to be easily scaled to other size classes. It can also be modified for different diameter arms by changing one parameter.

Why Did You Use Wood?

I use birch plywood and basswood for all of my prototypes because:

- Its cheap. For $30, I have enough wood to build 3 frames.

- Local arts and crafts stores have it in stock.

- Its easy to cut.

- Its easy to glue.

Once the wood version passes all of my tests, I can build it again with all carbon fiber and have something even lighter and stiffer.

How Stiff is This Frame?

While the birch plywood I used for this frame isn’t as stiff as carbon fiber, its better than most H Frames I’ve tested. I just made this short video comparing my Drogon v1 “X” frame, an H4 Alien 680mm frame, and my v2.4.6 wood frame:

a few points about the video:

- A true X frame (where the arms are continuous) has no problems with torsional stiffness. That’s just how an X works. When you separate the arms in the center and join them with top and bottom plates, you don’t have a true X anymore. But, you can’t run wires through continuous arms.

- My wood frame is almost twice as stiff as the Alien 680 frame. You can grab the front and back of the Alien 680 frame body and twist it with your hands. You can’t do that with my wood frame.

- Even though v2.4.6 is fairly stiff, its not as stiff as it could be. Yes, if it was built from all carbon fiber, it should be stiffer. But I made some slight design changes in v2.4.7 that I think will make it even better. I’ll list the details below.

Cheap and Easy to Build

Besides weight and stiffness, I consider a few other factors when I’m designing a frame for this blog. How expensive is it going to be? Are the materials easily available? What kinds of tools are necessary. For a DIY community, I think these factors are just as important as any others.

I live in a fairly small apartment. I have no garage. I have no workshop. I have an assigned parking space. I build most things on my living room floor. I have a nice collection of basic tools but I don’t have a 3D printer, or a CNC router, or anything fancy.

I built the whole frame in a day. I went to Michael’s Arts and Crafts and spent $29.55 on two pieces of birch plywood (1/8" and 1/16"). I went to Home Depot and got some Titebond II Premium Wood Glue and some JB Weld Clearweld Epoxy (the epoxy is for attaching the carbon fiber tubes to the wood frame body). I used one electric saw to cut all of my wood and carbon fiber. Its a Rockwell BladeRunner X2 that I got on Amazon for $100. I’ve had it for 3 years now and I love it. I used a sanding block, and some emery nail files from the beauty supply store. The next day it was ready for stress testing. It took me longer to create this post (including shooting and editing the video) than it did to build the frame, lol.

The Design, v2.4.7

(Click the image to download the full size drawing from Dropbox)

I make these drawings to be printed at 100% scale. When printed properly, you can put a centimeter ruler on it and the grid lines will be exactly 1cm squares. I put the JPG file on a thumb drive and I go down the street to FedEx Office. They have a printer that lets me make 24" x 36" monochrome prints for $3. Back at home, I use the drawings as templates to align and glue the pieces together. I use the guides on the drawing to mark where I’m going to cut the pieces.

Changes from 2.4.6 to 2.4.7

The frame is upside down in the first picture and torsion tests. The middle is open at the top and the ends are open underneath. I did this mainly to save weight, although I also wanted access to the wiring from the motors as it comes out of the tube ends. The middle section is open on the top for similar reasons but I’ll get into that in another post. In 2.4.7, the bottom plate now covers the entire frame body. I believe the advantages outweigh the savings of a few grams. I’ll just have to be more precise when I cut holes in the top plates for the motor wires.

Next, I found weak points where S1 and S2 ended at W1 and W3, forming the corners of a box. By extending S1 and S2 so they meet X1/X2 and X3/X4, it will create a stronger frame that should be stiffer as well.

Finally, the frame I tested in the video only has D1 and D2. I may or may not add D3 and D4 as I’m going to test it with the first two modifications before I add the extra diagonal braces. Since the middle section will remain open at the top, I can add D3 and D4 later.

A Note About X1/X2 and X3/X4

I should probably add a note about this in the drawing itself, but X1, X2, X3, X4 are continuous pieces with notches so they interlock. Each one is 118mm long. The notch is NOT is the middle so its best to cut the pieces and then use the drawing to mark where the notches go. This is where I use the emery fingernail files to angle the notches until both pieces fit together nicely and sit at the properly angle without having to hold them.

If I decide to add D3 and D4, they will also be notched so they interlock with D1 and D2.

Copyright?

My intention is to post these drawings and plans for everyone to use freely. At the same time, I want to keep my name on them and I don’t want them used commercially without my permission. I’m thinking its the same as my photography, where I can post my photos on social media and everyone can share them, even though I still retain my copyright. If anyone has suggestions, feel free to DM me.

That’s all for tonight. I have a LOT more coming!